https://www.spatialsource.com.au/the-future-of-construction-site-layout-is-here/

HP SitePrint improves accuracy and speed when doing site layouts, and eliminates the chance of manual errors.

PARTNER FEATURE

A quiet revolution is taking place in the building construction sector, with new technology offering the opportunity for both construction and surveying companies to boost efficiency and productivity.

A case in point is the new SitePrint autonomous robot from HP, available in Australia through C.R. Kennedy, which offers a quick, accurate and easy way to accomplish construction site layouts. The days will soon be gone when one or more staff members have to set out layouts manually.

The HP SitePrint’s streamlined workflow and intuitive interface enables construction teams to quickly and accurately print precise building layouts, which not only saves time but also reduces the chances of errors and rework, resulting in smoother project execution. In fact, a single operator can efficiently complete an entire building layout. And its ability to navigate complex environments and print text directly onto the site surface enhances project efficiency and cost management and minimises delays.

HP SitePrint also offers cost advantages, as you know what you’re getting when you set it to work. Automation of the layout process enables construction companies to gain greater control over their budgeting and cost management, reduce the need for manual intervention and freeing up time for professionals to tackle other, more valuable tasks.

The HP SitePrint’s user-friendly interface and intuitive controls simplify the adoption of digital tools and processes and enable construction teams to quickly integrate the robot into their workflow. In the words of C.R. Kennedy’s Chief Marketing Officer, Douglas Kennedy, “This product will allow surveyors to no long just be involved with site set out, they will now be able to do site layout.”

Safe and efficient

The HP SitePrint is fully integrated into the users’ workflow, using the same software used for other robotic total station tasks on the job site. HP has partnered with the main players of the positioning industry to ensure the HP SitePrint is compatible with their products. For instance, HP and Leica Geosystems, part of Hexagon, have collaborated to integrate HP SitePrint with the Leica TS16, Leica iCON iCR80 and Leica iCON70 robotic total stations. These are extremely high-quality total stations, each with the ability to repeatedly position the HP SitePrint robot comfortably within the 3 mm level of accuracy specified. Leica instruments are famous for their ability to precisely track and lock onto a prism, which is mounted on top of the SitePrint, so the risk of errors is mitigated and rework costs are kept to an absolute minimum.

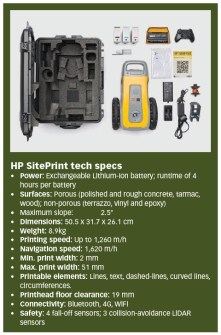

The HP SitePrint is smart when it comes to safety, too. It incorporates two sets of sensors: a first set that prevents collisions, and a second set that is hardware-activated and prevents accidental falls by continuously monitoring its environment to detect any potential obstacles, cliffs or depressions. And with a printhead positioned 19 mm above the surface, it avoids bumps and scrapes and enables printing in areas that don’t require a broom-swept floor.

Traditionally, “Surveyors often leave marks (grids) on site which other trades use to layout out their work,” said Alex Richardson, Building Construction Consultant with C.R. Kennedy. “The trades often use tape measures and chalk lines, but these are now under scrutiny as chalk lines can disturb potential silica dust on many construction sites… not to mention other health problems such as ongoing knee and back problems.”

Putting HP SitePrint to the test

The process of using HP SitePrint is easy:

- Prepare your 2D CAD drawing.

- Clean and prepare the site surface.

- Set up your robotic total station and shoot the control points.

- Lock the robotic total station to the HP SitePrint robot’s tracking prism.

- Connect the robotic total station wirelessly to the HP SitePrint robot through the user interface (tablet, phone, laptop, etc).

- Open the CAD file on the control panel, select the print area and submit the job.

- Choose between different inks for different types of layouts.

- Set the HP SitePrint to work.

HP claims that layout productivity can be boosted by up to ten times compared to traditional chalk-line layout, with printed on-slab text helping to deliver more accurate executions as per the plan. Complex layouts such as intricate arcs and circumferences are easy, and SitePrint can print on most common surfaces thanks to HP’s expertise with inks.

“On our first day with the device we did a competition between SitePrint and a manual layout team of four people. The HP solution laid out seven or eight rooms in the time it took the manual team to do two or three!” said Gerardo Rivera, COO of L5 Drywall. “Now we can free up resources to start laying out track much earlier, helping move the project forward faster.”

“The accuracy also impressed us,” Rivera added. “Make a couple of errors during the [traditional] layout phase and you end up ripping out walls later in the project — eating away at your margin. With HP SitePrint you can help eliminate mistakes and move weeks ahead in your schedule.”

HP SitePrint promises to transform the construction industry and boost the role of construction-sector surveyors. By enhancing efficiency, maximising resources, accelerating digital adoption and ensuring cost predictability, this innovative tool enables construction companies and surveyors to unlock the full potential of technology in their operations.

For more information about the HP SitePrint, visit C.R. Kennedy at survey.crkennedy.com.au.