CSD Group Australia were recently engaged for pre-construction works for the Aldi supermarket at Indooroopilly Shopping Centre, set to open late in 2019.

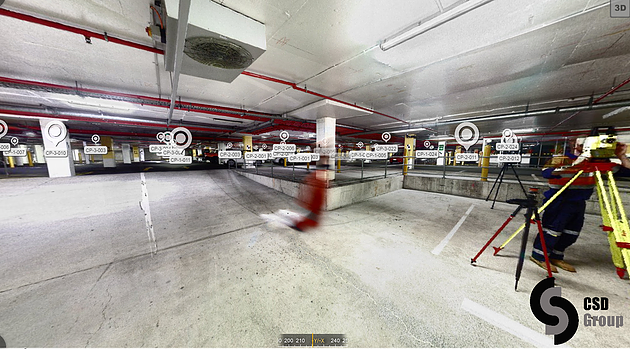

The project involved reinforcing the carpark roof deck below with additional steel supports. Initially CSD Group performed a laser scan and digital measurements prior to detailing the steel supports that will be installed beneath the new store.

Both the laser scan and digital setout were undertaken simultaneously and took just one day. CSD utilsed their in-house Leica ICON Setout Station (ICR85) to setout all concrete fixings and steel fitting plates

More Accurate Steel Drawings

Back at the office, the laser scans were processed and registered together to produce a compelete 3D point cloud of the carpark. The capture included concrete columns, pen marks showing Post Tension (PT) cables, conduit locations in the undercroft of the carpark as well as rebar in the concrete columns.

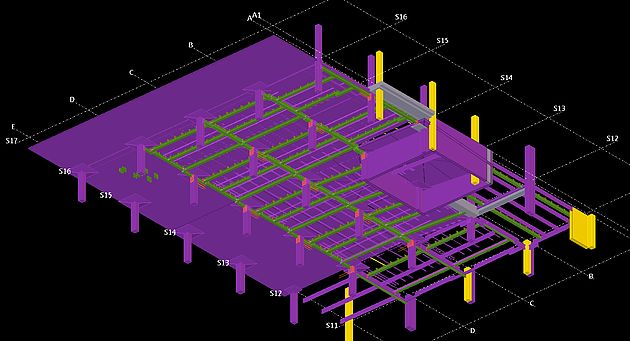

The point cloud was imported into Tekla Structures to begin steel design, avoiding the existing structure and elements.

Despite the architectural design having regularly spaced brackets and beams, the site scan determined that:

- Some steelwork had to be redesigned to be installed to the carpark undercroft. The redesign resulted in cost savings, easier installation and faster fabrication while maintaining structural integrity.

-

All steel was to be fixed to the underside of slab with masonry anchors at 1m centres. We managed to avoid all PT cables as marks (scanned by others) were all picked up. Beams were fixed to existing concrete columns with first fix bracket t-plates, each with six (6) Hilti fixings. All rebar marks were picked up by the scan, so all 16 brackets were modelled individually to miss the rebar. Each bracket ended up being different.

-

Columns were not square to each other and many rotated. This would not be picked up with a tape site measure. The ceiling is sloping, so the steel is not all at the same level. It was adjusted to make grout between top fix plates and ceiling to a minimum.

The new steel model was re-imported to the point cloud in correct position. Using virtual reality (VR), a “walk through” of the carpark was also done while in the office. The VR enabled us to do a more enhanced clash check between new and existing structures.

Had the site scanned not been preformed, the original structural design would have resulted in extremely low headroom, in some cases below minimum 1950cm floor to ceiling/beam heights for this carpark.

Digital Set Outs – The Biggest Cost Saver

Capturing measurements digitally is more accurate and less laborious than using a tape measure.

CSD Group utilised their Lecia ICON ICR85 unit on site capturing points which would geo-locate the site.

The ICR85 unit was taken back to site to setout all drill hole positions for existing structures (concrete and steel). These holes would have taken over a week for a team of site workers to manually mark out with a tape measure and laser levels, accounting for human error.

Using the ICR85 unit approximately 350 site drillings were accurately marked out by CSD technicians in hours, by one person, with all human error taken out of the equation.

In Summary

Laser scanning and digital setout benefited the Aldi Indooroopilly Project in the following ways:

-

More accurate steel drawings

-

Minimal to zero chances of steel rework and clashes with PT cables, conduits, rebar, pipes

-

More accurate measurements

-

Less time spent on site

-

Extensive 3D site survey that can be uploaded, viewed and referred to offsite anytime, anywhere, minimising the need to return on site

-

Point clouds may be utilised for other purposes by the project manager

-

Faster turnaround time

-

Cost savings, especially on digital layout

From original article published Aug 1st 2019 https://www.csd-site.com.au/single-post/2019/08/01/Laser-scanning-digital-set-out-ensure-clash-free-steel-support