With their continued expansion into international markets, most recently into the USA, Modena's Scan&Go is also reaching new heights Down Under.

Scan&Go's patented self-leveling extension systems for laser scanners have aready been adopted by the Sydney Aiport Corporation for perimeter capture (above) as well as highway scanning by WSP-Opus in New Zealand.

“The Scan&Go vehicle mount was easy to install and enabled our team to survey sections of the road without having to risk their safety” Graham Watson, Senior Engineering Surveyor with WSP-Opus.

Advantages of SCAN&GO patented system

Responding to the ever growing demand for 3D Laser scanning, Scan&Go founder Mr Massimo Secchia (below) developed a self-leveling extension system which would combine the accuracy of terestial laser scanning with the safety and efficiency of mobile laser scanning.

The Scan & Go system is easily mounted to any vehicle and eliminates the need for setting up in multiple locations, whilst preserving the accuracy and precision of data, optimising logistics and to obtaining maximum instrument performance.

This method of 3D topographic survey allows to obtain many advantages, both in economic terms and as regards the simplicity of use:

- Can be installed on any vehicle

- Can be used with any model of laser scanner

- Extreme ease of installation

- Surveys time extremely low

- Measurements can be performed by a single operator

- Non-invasive survey

- Restitution of the reality and an excellent accuracy in the positioning of surveyed points

Joining Scan&Go 2017, Ms Cristina Valchuk (pictured here with Mr Massimo Secchia) liaises with the current distribution partners and establishes new global markets.

Name: Ms Cristina Valchuk

Education: International Relationships

Position: Sales Director

Best aspect of the role: The possibility of communication with the customers and distributors all over the world, learning the market and business mentality of different nations and countries

Languages: English, Ukrainian, Russian, Romanian, Italian

Typical lunch: Sandwich with prosciutto and mozzarella

Favourite drink: Coffee (of course J)

Past Time: Walking

Most interesting fact of the Scan&Go story/history:

The “Scan&Go” methodology was created to achieve faster and more effective use of the terrestrial Laser Scanner in the branch of the traditional survey and to allow a daily use of it even in classical topography.

The idea of Scan&Go was to create a topographical survey system that allows to obtain the geo-referenced point cloud during the scan session, with a significant decrease of working time and increase of measurement range of any laser scanner.

That’s how the hart of all Scan&Go systems, the first Level Plane (automatic leveller) was born in 2014.

Favourite customer/client story: The customer was so impressed after the demonstration of the lifting system (Level Lift Roof) that has decided to purchase it before purchasing any laser scanner

Favourite Product:

Level Lift Box, manual lifter of 1 meter height with Level Plane16R, automatic leveller.

CR Kennedy's Sam Hesper tests a Scan&Go unit at our Port Melbourne HQ.

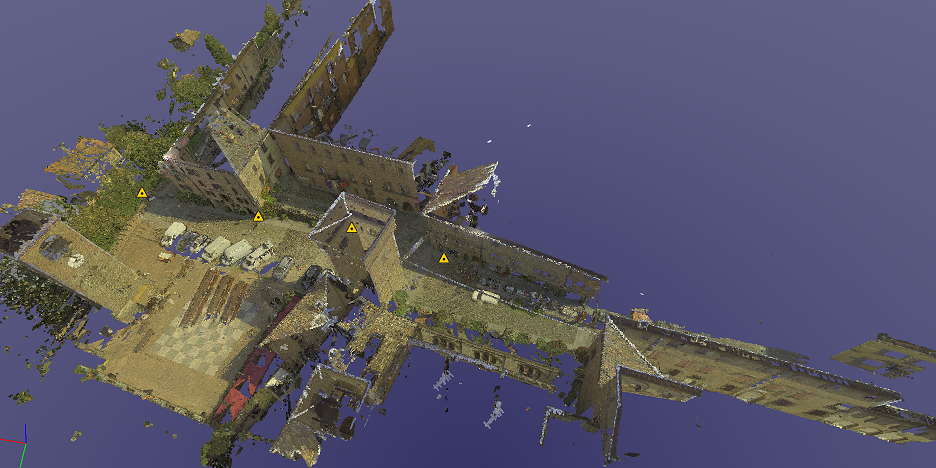

Most interesting use case: Laser scanning at 6-metre height and 20 kilometres per hour with the RTC360 mounted on a vehicle roof in Casteletro di Modena, Italy.

Mounted on the Scan&Go System, the RTC360 captured at 2 million points per second the centre of Castelvetro di Modena, Italy, in only a few minutes. RTC360 mounted on the level lift roof and automatic LP16R leveller. The first scan has been made in the centre of Castelvetro di Modena from a 3-metre height. The remaining three scans were done at a 6-metre altitude from the ground using Scan&Go vehicle installation.

The height of the scanner allows to overcome the obstacles present and increases the scanning range and its accuracy of measurement. All scans are perfectly levelled –this eliminates vertical variations. Our satisfaction of the test made is very high. This approach ensures the safety of the operator and the instrumentation in the field and increases the productivity of the RTC360.

The aim of the test was to verify the potential of the new RTC360 in combination with the Scan&Go system for laser scanning in mobile “stop” and “go” mode with the instrumentation installed on the vehicle.

The results obtained with the RTC360 are very good. During the scans, the system is very stable ensuring maximum measurement accuracy. It is very fast because the 3D laser scanner is mounted on the vehicle and you do not have to disassemble anything during the movements between one scan and the other.